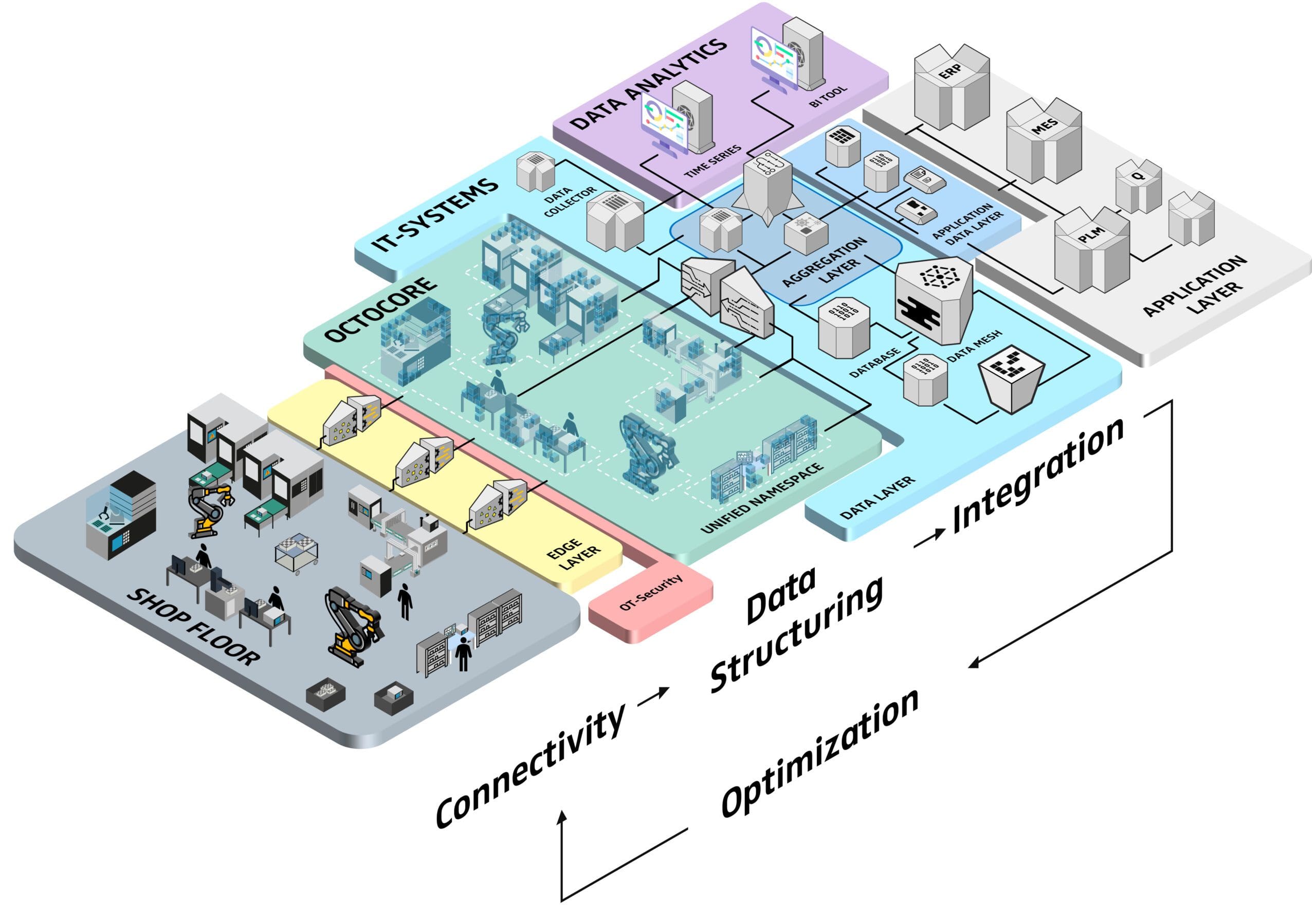

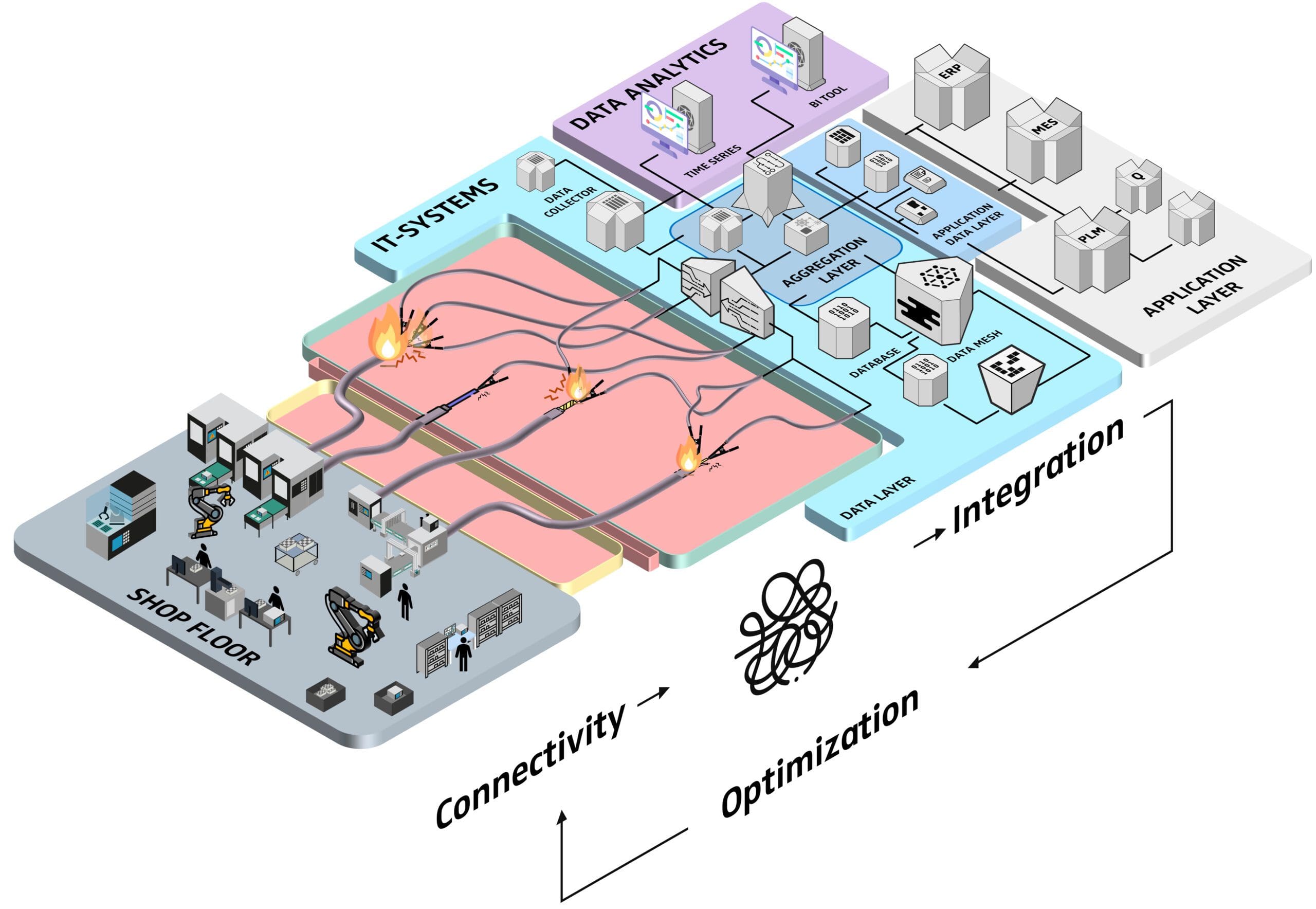

Octotronic empowers your smart factory with OctoCore, built on the Unified Namespace. Our unified data platform makes digitalization scalable by bringing OT and IT together, breaking data silos, and providing full data transparency.

With our modules and low-code environment, you can easily create everything from simple dashboards to advanced AI use cases. Plus, our Smart Factory Consulting and Integration Services ensure a seamless and tailored digital transformation.

At Octotronic, we consider ourselves Smart Factory architects. We believe that a strong data foundation, built on unifying and structuring data, is crucial for scaling use cases and technology on the shop floor. Alongside this, our versatile software modules and seamless third-party integrations empower you to implement diverse use cases faster, more scalable, and cost-efficiently than ever before.

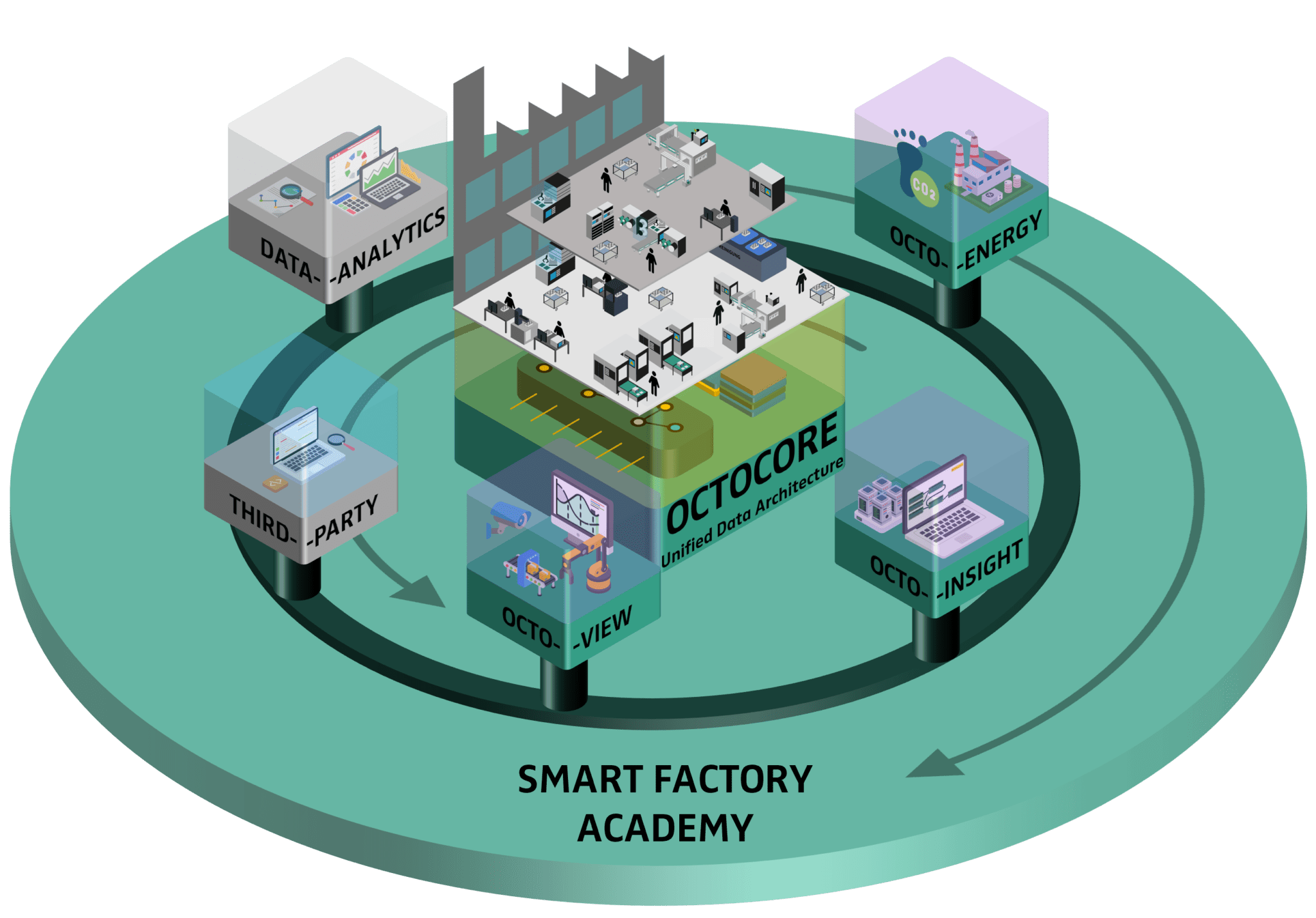

Unified Data Platform specialized in connecting, structuring, and aggregating shop floor and business data.

Build simple dashboards and monitor your OctoCore data (incl. time-series & video data) with OctoView.

Extract valuable insights from your OctoCore data with our low-code AI Analytics platform, enabling process optimization and predictive maintenance.

Optimize energy use efficiently by leveraging OctoCore data and energy provider information.

Learn from Smart Factory Architects through OctoAcademy and become Smart Factory Architect.

Manufacturing is not a green field. Seamlessly integrate OctoCore data with a variety of visualization and analytics tools.

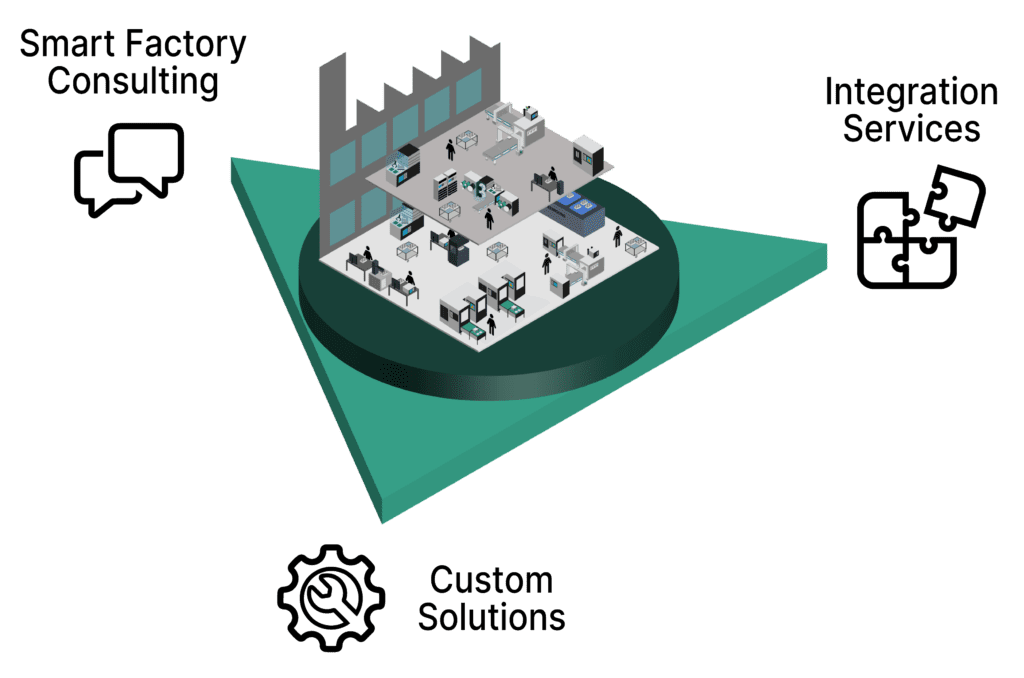

Successful digital transformation in manufacturing requires more than just advanced technology. It requires a strong partner with a holistic approach that includes expert guidance, seamless integration, and tailored solutions. Our Smart Factory productsare supported by three essential pillars: Smart Factory Consulting, Integration Services, and Custom Solutions.

We are your trusted partner to work together on their smart factory digitalization strategy. Step by step, we will assess your current status and help set up your smart factory data architecture for the future.

With our long-standing industry experience, we not only integrate and scale our solutions with you but also identify and incorporate third-party solutions.

The shop floor is complex, and there is no one-size-fits-all solution. That’s why our industrial and software engineers are here to meet your specific needs.

#OctoView

The digitalization of our rework process by Octotronic has accelerated our workflows. Thanks to their solution, we were able to reduce our rework effort by 30%. Additionally, access to our data has been significantly sped up by a Superset dashboard. Now, we can effortlessly access product data from the past 5 years and analyze and filter it interactively. Octotronic has helped us work more efficiently and opened up new analysis possibilities. We are very satisfied with their professional and customer-friendly approach.

Reto Jäggli

Data Scientist | Festo AG

#OctoCore & OctoInsights

Thanks to Octotronic, we can continuously expand our knowledge in the areas of data connectivity, data acquisition, data structuring, and data analytics. Among other things, our process engineers benefit from valuable tools for analyzing and further developing our system processes. Today, the gained data transparency allows us to better understand and positively influence the manufacturing processes.

Richard Scheiber

Head of Production

#Smart Factory Consulting

In our one-day Smart Factory workshop, we worked on a concept for a control room in the production environment. Octotronic understood our wishes and expectations and showed us what a possible solution could look like, using which tool. The workshop was very good and engaging, and it laid a solid foundation for the project start.

Lukas Kuhn

Project Leader Digitalization | Dätwyler IT Infra AG

#Smart Factory Consulting

Through a few workshops, minimal resources, and a truly lean budget, we laid the foundation for our 'smart factory.' The first prototype was set up within just a few weeks and helped to excite management about the nearly limitless possibilities. Thank you, Octotronic.

Urs Eggerschwiler

Head Manufacturing Automation a.d. | Schurter

#Smart Factory Consulting

Octotronic has helped us to clearly articulate our digitalization strategy. For us, this is essential to bring our customers and employees along on the journey.

Daniel Wahler

CEO a.d. | Stoppani Contract Manufacturing AG

#Custom Solutions

In collaboration with Octotronic, all data flows were quickly, easily, and clearly defined. The resulting and provided interface specifications were of very high quality. The integration of the MPI module went smoothly and required no significant rework. Through the MPI module from Octotronic, we were able from the beginning to work against a real system and avoid later rework, which often occurs with test systems. All in all, it was a consistently positive experience, both from a technology perspective and in terms of collaboration.

Matthias Binder

Software | transnova-RUF

![]()

#Smart Factory Consulting

Our project goal was to integrate the production steps during manufacturing and to capture a complete set of parameters and measurement values for each manufactured assembly part. Octotronic supported us during the workshops by fully recording a data flow process for an assembly inspection and installing automatic data acquisition across the entire process module. With this approach, rejection rates were consistently lowered across all facilities, and assembly production can now be carried out systematically with more consistent and better quality.

Metie Morina

Manager IT Production Systems

#Smart Factory Consulting

With the use of an MPI module from Octotronic, all relevant data flows could be quickly and easily integrated across system boundaries. The MPI module enabled the definition of clear interfaces as a 'Single Point of Contact' already in an early project phase. All changing framework conditions could be responded to without coordination issues in the project. This made it possible to develop and test against the defined interfaces and ultimately ensure a fast and reliable integration into the production system. A positive experience.

Tobias Zengel

Project Manager Automation Vascular Intervention

Making Digital Transformation of Operations Scalable & Cost-effective

Octotronic AG, Technoparkstrasse 1, 8005 Zurich, Switzerland

© 2024 Octotronic AG, All Rights Reserved | Privacy Policy